Global supply chains are in a state of flux, with growing pressure to be more sustainable, more reliable, and more efficient than ever. With technological advancements driving constant change, legacy systems and infrastructure are evolving at pace.

For businesses that send their goods around the world, this makes the operating environment increasingly challenging. They now face a triple bottom line – with complex reporting and regulation frameworks required to show how they care for their people and the planet, while they strive to maintain healthy profit margins for investors. Increasingly, there is little room for error.

Enter the wooden pallet. It is estimated that there are more than 3 billion in circulation in the European Union. With little evolution in design since the creation of wooden pallets 100 years ago, the problems they pose are well-known, including poor hygiene, low health and safety, and weakness, which results in considerable losses in transit and storage alike. They are also some of the world’s largest contributors to deforestation, releasing tonnes of CO2e at end of life.

Companies striving to achieve sustainability and efficiencies are rightly demanding an alternative.

So, what does the future look like?

It’s inevitable. The wooden pallet is dead, and the sustainable plastic pallet is born.

“Our customers are looking for a solution that is fit for purpose,” says Carl McInerney, group general manager at PalletEarth. “One that is dimensionally stable and capable of working within their automated warehouses; one that provides visibility of their goods wherever they may be in the world; one that is clean and light for employees, but strong enough to protect their goods in transport.”

With growing economic pressure, McInerney says companies are also looking to reduce time and cost. “If they are going to implement a new system, the cost must stack up.”

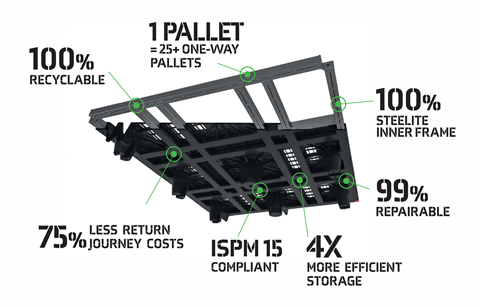

Investment in the next generation plastic pallet – which is stronger and repairable – achieves exactly this, lasting longer and ultimately costing less. They sustain less damage and avoid constant recall and repair. “And because we track every pallet with proprietary technology, we never lose them. Anyone who’s ever had a huge invoice for lost pallets understands this benefit,” says McInerney.

The benefits are endless

With circularity as a default, and technology built in to digitise the end-to-end supply chain, strong and sustainable plastic pallets are the future.

“Manufacturers, growers and procurement officials alike are looking for solutions that have sustainability at the centre core of their offering,” says McInerney. “We are thrilled to be working with change minded retailers and suppliers across the UK and Europe, who are witnessing the benefits across their systems.”

Early adopters include fruit importers who are focused on reducing their carbon impact, product damages, food waste and cost.

“They are now seeing benefits of space-saving, improved hygiene and health and safety, and reduced cost per pallet trip. With these solutions now locked in, they’re embarking on future-proofing and digitising their supply chains with our tracking and management information,” says McInerney.

PalletEarth has also been working with a shipping company, adapting their trackers to locate and avoid losing containers while rapidly improving cycle times.

“A core part of our offering at PalletEarth is to reduce our impact on the planet, while prioritising efficiency and economies. This is part of the DNA of our re-usable, repairable and recyclable pallets.”

So, why PalletEarth?

The future is only heading in one direction. PalletEarth has developed the strongest, most technologically advanced pallet with sustainability as a default.

If you would like to hear more about real world case studies, and run the numbers for your own business, contact Carl McInerney for an in-person supply chain consultation on +44 (0) 7879 428 489 or email c.mcinerney@palletearth.com