Roberto Zanichelli, business development and marketing director at Ilip, offers his insights into the changing dynamics of the fresh produce packaging business

What are your main hopes heading into 2024?

Roberto Zanichelli: The sector during the last two years has certainly had issues due to the rising energy and raw materials costs as well as inflation, which led to increasing prices for fresh produce and a reduction in consumer spending and consumption. For 2024 we are aiming for more stability in costs and hope for an easing of the inflationary trend so that we can better plan our strategies and investments.

On the other hand, these are challenged by the revision of EU legislation on packaging and packaging waste that will deeply affect our business and, paradoxically, will undermine the opportunities around the sustainability of our trays and punnets made with recycled PET in a tray-to-tray closed loop system.

What has Ilip been focusing on?

RZ: We keep pursuing our sustainability strategy for our packaging because the interest of retailers, packers and consumers in this topic remains high, especially when it comes to the origin and end-of-life of the product they buy. Therefore, we are strengthening our production capacity for tray-to-tray R-PET in a closed loop system, which is part of our three-pillar policy on environmental sustainability, the 3Rs: reduction of raw material use and food waste; recycling of plastic packaging in a closed loop in line with the circular economy concept; and renewable resources such as bioplastics.

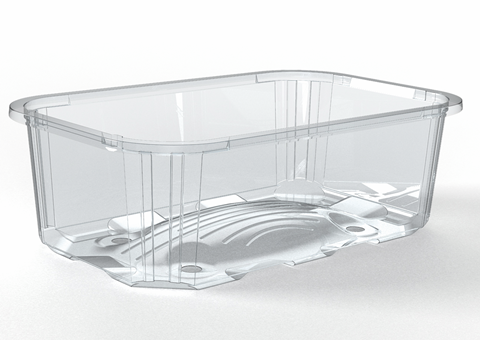

When it comes to new product development, we always keep sustainability and eco-design in mind. At Fruit Logistica we will showcase the Airwave, our padless heat-sealable punnet based on our B40s range, which has been designed to pack and protect soft and fragile produce without the need to have a shock absorber pad.

How strong is the market for your packaging products right now?

RZ: As you know the fresh produce business can be affected by climate and crop yield. In the last couple of years, we experienced some discontinuities to our usual supply volumes, mainly in southern Europe, that have been mitigated by new opportunities that we caught on the market and by the fact that we serve over 50 markets worldwide in both hemispheres.

However, we can confirm that current and modern supply and value chains, from field to packer and from distributor and retailer to consumer house, need and prefer pre-packed fruit & vegetables to be more effective and efficient, with reduce wastage, whilst improving sustainability, profitability and consumers’ convenience and satisfaction.

On the other hand, we also acknowledge that the packaging market for fresh produce in Europe is in a state of transition as it adapts to changing consumer preferences and, above all, regulatory requirements that can have a deep impact.

We have seen rising costs and global economic turbulence in recent times. How have you adapted?

RZ: Since the post-Covid supply chain shock, we have adopted several strategies to cope with this situation whilst maintaining a certain flexibility in order to adapt to market changes. Firstly, we intensified our efforts to reduce costs wherever possible, through a series of initiatives that covered both production and operating costs. Secondly, we had to reduce the gap between cost increases and sale prices, so we gradually increased sale prices when needed. In addition, we tried to increase our revenue sources by differentiating our business proposition into new markets and products with higher added value. Finally, we invested in innovative technologies and digital solutions to improve operational efficiency and reduce long-term costs.

What are you showcasing at Fruit Logistica in Berlin?

RZ: Besides the B40 padless range we will showcase the new product developments of our Sprint department, specialised in the design of customised products with a short time to market as well as our ‘ezy:split’ punnet, the first hybrid punnet made of recycled PET and cardboard for premium fruit packaging. The cardboard support, which guarantees excellent stability, enables the weight reduction of the plastic component by 45 per cent and offers excellent branding and communication possibilities thanks to the printing areas on both sides.