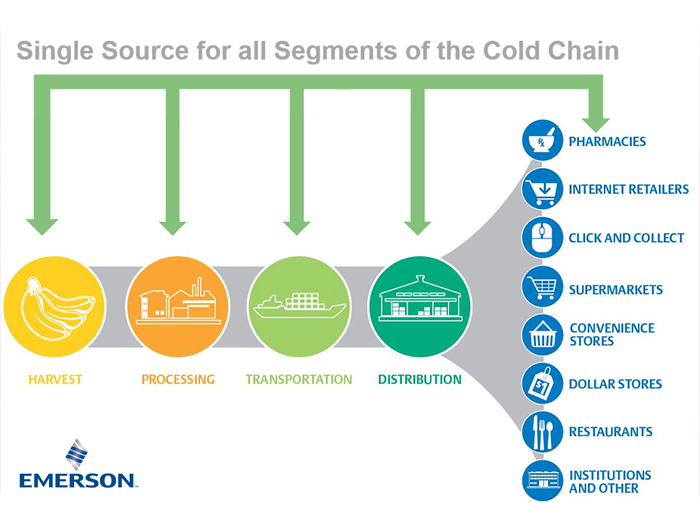

Instead of reacting to a food safety transport incident, Emerson recommends a proactive approach – one that mitigates risks, reduces shrink, protects your brand, and modernises your supply chain.

First, recognise that freshness is cumulative. The perishable supply chain is complex, with many hand-off points. If temperature abuse occurs in any segment, food quality and safety can be compromised, shrink occurs, and your brand may suffer.

Second, recognise that technology has advanced significantly. Automated temperature monitoring records can be generated in both real and near-real time with no human intervention. It is time to leverage these technology advances and modernise your programme.

Step One — Establish pre-cooling processes

First, before product is transported, it should be pre-cooled by the supplier to the correct transit temperatures. It is important to get the thermal mass of the perishable product to the correct temperature before shipping, as this can have a direct impact on product quality, safety, and shelf-life.

If the product is not pre-cooled, it can continue to breathe in the enclosed truck trailer or container. In some cases, the product will actually generate heat – called respiration – which results in product degradation.

Product should be pulped to ensure proper temperatures have been reached before loading begins. Successful temperature control starts at the beginning with the supplier.

Pre-cooling of the transit container by the carrier should occur when the container is connected to the coldstorage unit. This is because product temperature and container temperature need to be in equilibrium.

A container not connected to a coldstorage unit should NOT be pre-cooled. This is because when doors are opened and loading occurs, hotter air will enter the container, causing condensation. This can create numerous problems including the formation of ice, and structural damage to shipping containers.

Step Two – Establish proper loading practices for optimal air circulation

Product should be loaded in a manner that promotes air flow through the transport container. Product should not be loaded above the ‘load’ line. In addition, the product packaging itself should promote air flow.

Step Three – Establish and communicate proper transport temperatures

After pre-cooling and proper loading, product is then shipped to distribution centres within temperature ranges that are acceptable for the commodity in question. This practice should be considered for any perishable products backhauled to the distribution centre as well.

The following are the commonly accepted transport temperature ranges for various commodities that you can communicate to your supply chain stakeholders:

Bananas

13.3°C to 16.6°C

Tomatoes, yellow onions, potatoes

5.5°C to 12.2°C

General produce

0°C to 3.8°C

(This is the largest category and includes leafy greens, apples, broccoli, carrots, cauliflower, mushrooms, green onions, berries, corn)

Meat (beef, pork, poultry, seafood)

-2.2°C to 3.8°C

Dairy

0°C to 3.8°C

General frozen food

-23.3°C to -9.4°C

Step Four – Temperature monitoring device and placement procedures

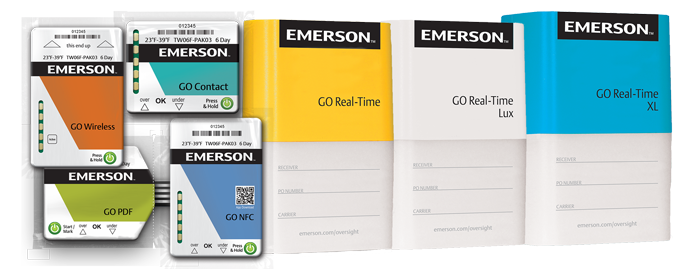

Place a digital temperature monitoring device on your load to monitor product temperatures as the reefer download will only provide ambient container reads and may not have been calibrated recently. These devices will give you the most accurate information. Establish consistent placement location(s) in the trailer.

Step Five – Receipt at distribution centre

When product is received at the distribution centre, quality assurance staff check the data from the temperature monitoring device for any temperature breaches. It is important this data is checked because it provides historical information on what happened to product during transit.

A pulp temperature upon arrival in and of itself is not sufficient, as it only provides temperature at that particular point in time.

There have been blind tests where product arrived at a distribution centre, was pulped, and shown to be at the correct temperature. However, when data from the temperature monitoring device was reviewed, it showed the refrigeration unit had been turned off for a significant amount of time during transit, creating the risk of product degradation and bacteria growth.

Although the damage might not be immediately visible, this temperature abuse would be apparent in the future quality and shelf-life of the product.

Temperature monitoring devices provide historical data and help prevent the receipt of substandard products. They are the ‘eyes and ears’ of quality teams when product is outside of their direct control.

Step Six – Distribution centre to store

Once product is consolidated at distribution centres, it is regrouped and sent to the individual store or restaurant location. Product is shipped either on company-owned vehicles or subcontracted out to carriers.

This area of the cold chain is subject to the same risks, but independent monitoring devices are often not used to check that temperatures have been maintained. However, freshness is cumulative, and Emerson recommends this segment be monitored to complete your continuous monitoring programme.

Step Seven – Stationary and yard monitoring

Don’t forget, perishable products held in stationary facilities are part of the cold chain. Make sure you address this segment with a facility monitoring programme.

It’s also important to consider product that is preloaded for shipment and waiting for transport in the yard. These temporary holding facilities should be monitored as part of your comprehensive programme as well.

Best practice summary

A world-class temperature monitoring programme includes the following elements:

- Recommended safe temperature transport range guidelines for the most popular commodities established and communicated down the cold chain.

- Requirement perishable products be pre-cooled to acceptable transit temperatures before transport begins.

- Documented handling procedures when loading into a container attached to a coldstorage unit versus a container not attached to a coldstorage unit.

- Temperature monitoring devices utilised on perishable products in all segments of the cold chain, including all in-transit and stationary monitoring. These recording devices will help suppliers, carriers, and retailers pinpoint where weak points in the cold chain exist so solutions can be implemented to mitigate risk, reduce shrink, and protect your brand.

- A system where temperature logs of your cold chain are available anywhere and on demand.

Remember, freshness is cumulative. Don’t wait for an audit or critical loss of product. Implementing these measures today will mitigate your risks, reduce shrink, and protect your brand.

About Emerson

With its headquarters in the US city of St Louis in Missouri, Emerson is a global technology and engineering company that provides innovative solutions for customers in industrial, commercial and residential markets.

Its Emerson Automation Solutions business is a leader in helping manufacturers automate and optimise their production processes using best-in-class technologies and industry expertise.

Emerson Commercial & Residential Solutions, meanwhile, develops technologies and services that improve human comfort, safeguard food, protect the environment, enable sustainable food waste disposal and support efficient construction and maintenance of buildings and municipal infrastructure.

For more information on end-to-end cold chain monitoring solutions, visit emerson.com/cargo