The Logistics Hub hosted a session on day three looking at digital platforms and how they could transform logistics operations

Speeding up supply chains and improving connectivity through digital innovation was the theme of the opening Logistics Hub session on the final day of this year’s Fruit Logistica.

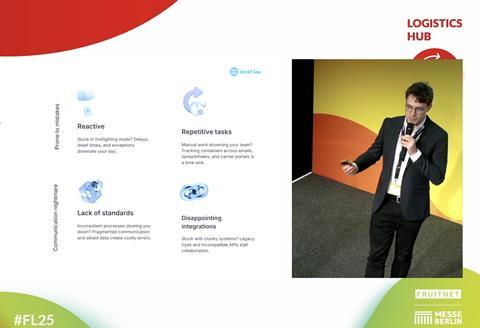

Michiel Valee, co-founder at Dockflow, was on hand to explain how the group’s logistics enablement suite offered solutions for smarter logistics – with the ultimate goal of making supply chains faster and more efficient, thereby reducing delays, increasing reliability, and ensuring fresh produce reaches its destination on time and in optimal condition.

Dockflow, he told visitors, provided container visibility for ocean-going containers.

“In principle, it should be very easy to ship a container from A to B,” Valee said. ”You book it and it gets delivered – very simple. But in practice, there are a lot of things that go wrong.

”We all remember the Ever Given blocking the Suez Canal. We also have port congestion, labour strikes, fire breaking out – there is almost always something going wrong, and at the very least the vessel schedule can get messed up, meaning less reliability of delivery.”

With these kind of events occurring more regularly, it was important to build resilience into supply chains, he explained, and this is where Dockflow came to the fore.

”We provide answers to questions by delivering a dashboard where we get data from carriers, from shipping lines, from terminals and satellite data, reliably tracking thousands of containers,” Valee outlined.

Dockflow launched its logistics enablement platform in 2021, and it has helped to reduce demurrage costs and time, increase visibility for stakeholders, cut claims and reduce booking errors, he confirmed.

The group was also working on a new project with Neolithics and the World Economic Forum, he noted, to gather data on fresh produce quality and tie it in with shipping data.

“We see a lot of freight forwarding companies, a lot of shippers, who have started to implement their own software because they think they are very unique, but in the end we are all shipping a container from A to B,” Valee commented. “While some processes will be different, a lot of the basics will be the same.

”They’ve built their own software but it’s very difficult to be a freight forwarder and a software company. The world is moving too fast.

“We have talked to a lot of these companies and after a few years the project did not realise its full value,” he said. ”One of the reasons to mention this is that huge cases can only be built on the basic data you have.

”If you want to do something with, for example, AI in future, you need to have your basics in order. And the basics at this point in time is having the kind of visibility data that we have. Only then can you build these type of advanced cases.”