Advanced grading and packing machines have long played a decisive role in delivering ever-rising quality standards, but it is their ability to limit human contact with the fruit, while offering complete traceability, that is gaining increasing attention during the current Covid-19 pandemic.

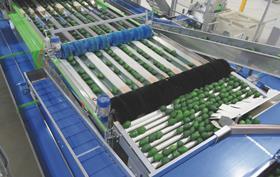

“The main demands for avocados are gentle handling throughout the processing line, high efficiency in sizing, grading and packing, and accuracy in terms of external and internal quality grading,” says Didier Izard, export sales manager at Maf Roda’s subsidiary in Valencia, Spain. “The aim is to optimise the packout for each category and market and to add maximum value to each batch of fruit. But the goal is also to optimise productivity and save costs in the packing process through automation and robotics.”

According to Izard, Maf Roda’s machines and solutions respond to all such demands, with customised turnkey lines and solutions produced in-house for avocado packers around the world.

“In our lines we receive the fruit in a gentle and careful way, washing and sanitising the product using sustainable processes, and remaining alert to water consumption,” he says. “We then select, classify and pack the fruit according to the different qualitative and quantitative criteria, enabling it to travel on long journeys to markets worldwide, always meeting the highest demands of the customer.”

Izard says that major developments have recently been made to provide solutions with more automatic and robotised packing systems. “This helps to reduce human contact with the product and ensure the gentlest handling to maintain the fruit’s quality,” he says. “Another key factor, which is taking on more importance in the current context, is to be able to identify and trace fruit batches throughout the post-harvest operations, guaranteeing full traceability from the field to the end consumer. Our lines serve to homogenise the criteria and qualities of avocados, allowing us to gain accurate information on the batches entering and leaving the packhouse and offering total traceability.”

Thanks to close cooperation with its customers, the company has also been able to improve its mechanical and optical sorting processes. “The new generation of external (Globalscan 7) and internal (Insight/IDD) non-destructive quality control systems has really improved sorting,” says Izard, “with more accurate surface analyses (colour, size, shape) and defect/blemish detection (scars, thrips, bites, friction) and quality measurement (oil content, ripeness, dry matter, internal grey flesh). We also have a brand-new grader, Pomone 125, which is suitable for longer and larger fruits like Hass and green-skin avocados, and works with all Maf Roda external and internal optical sorters.”

Crucially for its customers, Maf Roda’s machines – thanks to the use of technologies like AI, HD multispectral cameras, near-infrared spectrometry, and infrared and UV analysis – are also able to provide an online report detailing the characteristics of each fruit. “This allows users to precisely define their packing parameters based on the individual needs of each of their customers and markets,” says Izard.